The unprecedented capacity requirements of large social media, search, colocation, and cloud companies are driving massive investments in data center development. The organizations creating this capacity are continually experimenting with new technologies and designs to push the limits of data center performance while driving down costs.

Two examples: The increasing development of alternative power architectures using reserve power techniques and the advancement of new energy storage solutions. Both are beginning to show measureable impact.

Using the Reserve Bus Architecture to Streamline Redundancy

The 2N or 2N+1 dual-bus architecture has historically been the choice of high-availability data centers. When properly designed, these architectures eliminate single points of failure in the critical power system and allow maintenance to be performed on any component while continuing to power the load.

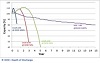

However, in today’s environment where the need to optimize capital expenditures and resource utilization is paramount, this level of redundancy is becoming more difficult to justify. Increasingly, the 2N + 1 or 2N dual bus architecture is being replaced by various reserve architectures pioneered in large colocation facilities (Figure 1).

The basic reserve architecture creates a redundant architecture, while maintaining fault tolerance and concurrent maintainability through the use of static transfer switches (STS). The STS allows a redundant UPS system to be brought online to pick up the load from any one of multiple UPS systems in the event of failure or maintenance.

This deployment does complicate maintenance and load deployment compared to traditional 2N architecture, but the economic benefits are compelling. Consider a 2N + 1 architecture consisting of six 1100 kW UPS modules. If the modules are sized to 110% of maximum load, the system is capable of supporting 2000 kW. Shifting to a shared reserve architecture, in which five of the modules are supporting the load with one reserve module, the same UPS capacity can support 5,000 kW. High reliability reserve architectures, such as break one/fix one, can also be achieved.

Variations of the reserve configuration can be considered. The primary difference in the configurations rests with how the client loads achieve power redundancy: either sharing a reserve system, dedicating the reserve system to high-priority clients, or accessing unused capacity across mul tiple UPS modules to create the reserve.

tiple UPS modules to create the reserve.

Using the Reserve Architecture to Mimic 2N

In the dedicated reserve architecture higher levels of availability can be supported by directly tying the reserve power to a specific client or application. This dedicated reserve ensures redundant capacity is allocated to support specific UPS loads. Colocation providers may use dedicated reserve modules to provide 2N backup capacity for customers requiring higher service-level agreements (SLAs).

Alternately, two reserve modules can be shared across multiple primary modules in a configuration that is commonly referred as “eight to make six” or “ten to make eight.” With this configuration, any module can be taken offline for service while maintaining redundancy across the system.

In a shared reserve configuration, the reserve power system is shared across more than one customer or application.

Utilization is slightly lower in a dedicated reserve than can be achieved with a single reserve module, but still higher than is possible in the traditional 2N architecture. Plus, new capacity can be supported through the addition of one module rather than two as would be required with a 2N system.

In a distributed reserve architecture, the reserve capacity is distributed among all the UPS busses in the system. In a 4 buss system for example each bus could be loaded to 75% with the remaining 25% held in reserve. If one buss goes off line its load is picked up by the other three. This complicates load management compared to reserve or dedicated reserve systems.

While reserve architectures provide the benefit of higher utilization rate they require more complex load management and more rigid maintenance methods. Care must be taken to not overload the reserve and extra care must be taken to assure proper connection of the dual cords. Often in a reserve system the dual cords are connected to the same UPS buss in an A to B or A to B, B to C, C to A configuration. This meets the SLA that requires both cords of the dual corded server to be connected to protected power at all times.

The reserve power configuration, whether shared, dedicated or distributed, offers significant flexibility in the quest for efficiency, speed and availability and these configurations have applicability within both colocation and enterprise applications.

Energy Storage Emerges

Is there a need for an improved energy storage solution? Users and managers around the world agree the answer is YES!

For the critical data center operator, the traditional lead-acid battery has been the go-to source to provide short-term ride-through time for the uninterruptible power systems. These professionals realize the necessity of maintaining vital systems running without disruption. They also witness many drawbacks to their current solution.

Although these drawbacks have been a longstanding problem, the alternatives to traditional valve-regulated lead acid (VRLA) are limited. Technologies like nickel cadmium and lithium polymer are viable only in certain applications, not yet in the data center. Fuel cells present an interesting alternative but they have limitations such as poor step load performance. This requires a super capacitor or batteries to bridge the time required for the fuel cell to come up to capacity.

A viable alternative available today for data center deployments is lithium ion. Lithium-ion batteries (LIB) increasingly are finding their way into the data center.

So the question asked is: Are LIB ready to share the stage with lead acid?

The Problem with Traditional Batteries

Experienced users know traditional lead acid batteries are most often the “weak link” in their data center’s power chain. With strings and strings of batteries required to support a modern facility, it might feel as if a possible failure is right around the corner. The batteries tend to be high maintenance, heavy and in need of frequent replacement. Innovations in monitoring, management and service have helped moderate some of these pains.

So, can the right lithium-ion battery provide relief? Let’s investigate.

Battery reliability: According to the Ponemon Research Institute’s 2013 study on data center outages, 55% of unplanned failures were tied to lead acid batteries. Follow up studies in 2016 have shown some reduction, but the magnitude is still startling. Given proper service and remote monitoring, we have demonstrated these batteries can be effectively managed, but this naturally comes with a cost.

Pain of replacement: On average, VRLA batteries supporting critical applications need to be replaced within four-to-five years. Given the number deployed, that can translate to a perpetual replacement cycle. And each time this occurs, it’s someone’s time, money and headache, not to mention the upheaval the site goes thru during the process.

Benefits of Lithium-ion Batteries

- Longer life: The lithium-ion battery chemistries found in data center applications have predictable life spans up to four times that of VRLAs. This translates into fewer battery replacement cycles and operational disruptions.

- Less weight: The comparative power provided in a LIB solution vs. a VRLA also brings a weight savings of up to 60%. This can reduce floor-loading thresholds, which in turn can reduce facility construction costs. LIB also open up the ability to place batteries in places that have been off limits to heavy VRLA counterparts, such as high-rise buildings. Reduced weight can also reduces shipping costs.

- Smaller size: LIB have higher energy densities than VRLAs. This fact not only saves weight, but also allows the solution to be up to 70% smaller. This means an organization can avoid big battery rooms. That space can either be repurposed, reduced or not included in designs, saving capital construction costs. Most organizations can find a more economical purpose for such space.

- Accommodate higher temperatures: Depending on the LIB chemistry, batteries can safely operate at higher temperatures without degrading. This can save on cooling costs over VRLA and open up more flexible location options.

- Longer shelf life: LIB can last up to 18 months without a top off recharge. VRLA require a top off every six months.

Are all LIB the same?

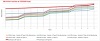

Not at all, there are a host of related family chemistries. There are about six common variants, as noted by the Battery University (Figure 2). Of these, experts tend to agree there are three to four best suited for a critical data center application – Lithium Iron Phosphate (LFP), Lithium Manganese Oxide (LMO) and Lithium Nickel Manganese Cobalt (NMC). A blend of LMO and NMC optimizes advantages of both types and is the choice found in today’s electric vehicles.

Live Long and Prosper

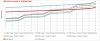

Battery life might not make for the best dinner conversation, but it’s still plenty interesting. There are various lives to consider: design life, warranty life and end of life. Take the common VRLA, which may have a design life of 10 years but a warranty of just three full years and a prorated warranty of seven. At 77°F, in four-to-five years the cells begin to fail. Given the criticality of the application, this means replacement should be implemented at this time (Figure 3). Some VRLA manufacturers are showing performance improvements with 15-to-20-year life designs. As expected, these additional years add substantially to the initial cost. Meanwhile, LIB lifespan shows patterns that are more gradual.

Cycle Counts and Depth of Discharge

It is generally accepted that LIB will provide a higher cycle count than standard VRLA. Exact numbers will vary depending on such things as chemistry, application and operating conditions. In his paper, Discussion on Lithium Iron Phosphate Batteries Used for IDCs Compared with VRLA Batteries, Shouzhong Yi notes that LFP are showing increased cycle counts on the order or 10x that of VRLA. Even at deep discharge application (80% depth of discharge [DOD] or more), he notes that LFP batteries can serve 10 years or more.

End of Life and Depth of Discharge

End of life (EOL) has a different meaning in LIB than it does in VRLA batteries. The EOL is set by increasing battery size by 125% so 80% life at end is equal to 100%. The VRLA hits EOL in year three-to-five vs. LIB, which hits EOL at year 13-15. Therefore, a LIB is at 93% when VRLA is at 80% EOL (Figure 4). Again, chemistries and conditions affect actual performance.

Trust but Verify

Battery monitoring and management is vital. Used correctly, operators can verify performance and initiate proactive service. With lead-acid, this became especially important. But, LIB management is equally as important if not more critical, especially during these formative years. Unlike lead-acid, lithium-ion batteries used with UPSs are manufactured with integrated intelligence that enables management and monitoring. It is recommended these systems tie into a system-level monitoring solution to expand the visibility and capability of the monitoring.

Safety First

All energy storage devices require some level of caution. You may have read about a few troubling consumer based LIB stories. The combination of energy density, small devices and specific lithium-ion chemistries provided designers unique challenges.

Fortunately, high-end commercial applications (as in UPSs) are not faced with the challenges of many consumer designs. The LIB for a UPS application utilizes safer chemistries, more spacious operating quarters, stronger packaging materials, and perform in less stressed user environments. All of which open the door for establishing greater safety precautions. In fact, leading LIB manufacturers utilize x-ray imaging to ensure every cell passes quality inspection. Safety fuses, overcharge protection, and stronger material construction are but a few of the built-in safety advances. In short, these aspects minimize the chance of thermal runaway.

Is the Price Right?

Our industry is on the pragmatic side. We expect initiatives to have ROI. Total cost of ownership efforts for LIB cases must tabulate the initial cost, installation, service/ maintenance, other operating costs, replacement expense, shipping and disposal. Ideally, we should include a reliability/availability calculation as well. Let’s look at some costs.

Not surprisingly, the initial cost of a LIB solution is higher than standard battery solutions at the current time. Present indications in North America point to a premium of approximately 1.75x that of a comparable VRLA deployment. We also know LIB prices have shown a decrease in the past five years and we should expect moderate reductions as the deployment rate continues.

Though LIB are not classified as “maintenance free”, the service and maintenance required is less than that of VRLA. In relation to the recycling and disposal situation, Lithium-ion batteries are considered disposable, but given the relative newness of LIB to the general market, the ecosystem for recycling has not yet matured. Most feel this will be addressed by the time replacement cycles appear.

A big factor in a cost model is related to the delayed replacement costs when compared to VRLA. Of course, this is a derivative of the LIB battery life.

Vertiv conducted a TCO comparison that took into consideration initial cost, service and maintenance, replacement and disposal using a variety of leading battery manufacturers. We evaluated scenarios based on a 1 MW load against two different run times (five minutes and nine minutes) across VRLA and LIB. This difference allows for real-life energy storage evaluations across various battery behaviors. The analysis (Figs 5 and 6) shows a return on the LIB investment begins just before or after the second VRLA replacement cycle. We did not include space savings, or the elimination of dedicated battery rooms in the TCO. Doing so would enhance the LIB return even more.

Bottom Line

With so many megawatts of data center capacity to be developed in the next several years, we can expect more evaluation of emerging power architectures on a greater scale and a continued push for innovation while optimizing costs, availability, flexibility and scalability. LIB TCO looks compelling today and will continue to improve as adoption rises.

Recent Comments

OTDR

Informative article!!

I attended too and was glad to see...