Prefabricated data centers are becoming increasingly attractive to hyperscale and cloud service providers, as well as enterprises building new data centers or expanding existing facilities. This appeal is based primarily on the speed at which new capacity can be brought online. Based on our experience at Emerson, prefabricated data centers — fully customized, free standing facilities constructed entirely using pre-configured and manufactured modules — move from conception through design, construction and commissioning, 30% to 60% faster than data centers using traditional processes.

Prefabricated data centers are becoming increasingly attractive to hyperscale and cloud service providers, as well as enterprises building new data centers or expanding existing facilities. This appeal is based primarily on the speed at which new capacity can be brought online. Based on our experience at Emerson, prefabricated data centers — fully customized, free standing facilities constructed entirely using pre-configured and manufactured modules — move from conception through design, construction and commissioning, 30% to 60% faster than data centers using traditional processes.

For many businesses, the ability to bring large blocks of capacity online months faster than they could previously has enormous commercial advantages. As a result, this speed of deployment will likely remain the major driver behind the growth in prefabricated data centers for the foreseeable future.

However, as we gain more experience with prefabricated data centers, we are discovering an unexpected benefit that ultimately may prove to be just as compelling as speed of deployment. The prefab process is yielding superior designs that are better matched to site requirements due to the collaboration among architects, consulting engineers, technology providers and construction companies.

If you want a data center that is holistically designed, features tight integration across systems and in which all major systems are tailored to the site, the prefab process is the best way to accomplish this.

That’s because power, cooling, and management systems have traditionally been configured independently from each other and independently from the building/superstructure in which they are housed. That is not the case with prefabricated solutions that leverage the insight and experience of technology vendors from the beginning of the process.

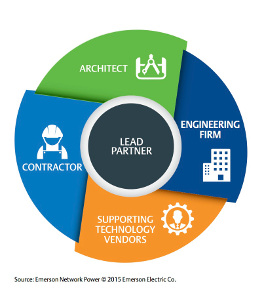

In the traditional serial design process the project is initiated by an architect, passed to a consulting engineer, then to a contractor, and finally bid to technology vendors. Prefabrication is different in that a lead technology partner manages the overall project, bringing together all of these parties at the front end. That not only saves time, it also increases collaboration as architects, technology providers, engineers, and contractors work hand-in-hand from the beginning of the project.

The key to unlocking this hidden benefit is choosing partners that are willing and able to collaborate. The lead technology partner plays a central role in this process by ensuring the facility is tailored to the site, meets desired efficiency and availability requirements, and is manageable and scalable.

Architects continue to play a vital role in the facility design process but in the prefabrication process their designs need to support modular construction, and input from other partners like consulting engineers in the early stages of the design is essential to accomplishing that. The project also gains from the early involvement of the general contractor and any secondary technology providers to ensure smooth execution during the construction phase and to provide additional integration perspectives, respectively.

Infrastructure vendors with strong service organizations are well positioned to serve as the lead partner on prefabricated projects as they have the technology expertise to help guide design, the facilities and resources to support fabrication, and the service organization to manage on-site assembly, startup and commissioning. Leveraging that expertise throughout the entire process, rather than just at the back end of the project, is proving to be prefab’s secret weapon.

Recent Comments

Enterprise Patch Management Policy

Hi Mr. Douglas, I really enjoyed this post....

IT management Support and Services

Modular construction discussion is very important for professional...

Good summary with a couple of questions: At...