Substantial sources of additional energy savings lie beyond data center design and in the effective management of the way we “operate” our data center facilities. According to Troy Miller of Glenmount Global Solution, “Effective energy management is easily found through the implementation of an automated PLC-based controls platform and proven controls algorithms for data center HVAC equipment operations.”

There are three key requirements for maximizing the efficiency of data center cooling system operations:

• Reliable and efficient cooling system “design”

• Applied “operations” expertise in central plant cooling systems

• Holistic optimization of the entire cooling system (chilled water and airside)

Mission-critical data center cooling systems are typically designed with additional capacity (often about 20%) to ensure the computing environment is not compromised. This design philosophy can be leveraged to our benefit to decrease the overall HVAC system power envelope by networking all of the cooling systems’ components through a layer of sensors and meters, and then by modulating their operations to normalize what is effectively idle or “stranded” cooling capacity. This approach levels out of the peaks and valleys of energy consumption while ensuring that critical cooling requirements are maintained.

The automation of these systems adds to the reliability of the facility by removing the possibility of human error associated with the continuous intervention in HVAC equipment operations while making incremental adjustments intended to improve energy efficiency, or “manual energy management.” Of course, these system improvements require that the data center owner rely upon new skill sets and quality controls systems, but the end result in my mind is by far worth the investment and change.

The benefits associated with this automation and algorithms energy management approach include:

- Reduction in human error associated with manual controls adjustments,

- Greater transparency in cooling system operations,

- Significant cooling energy cost reductions,

- Increase in power available for computing,

- Minimized HVAC power usage effectiveness (PUE), and

- Reductions in overall environmental impact.

Optimum Energy (OE) is a patented energy management solution that minimizes cooling system power usage in data centers through algorithms that continuously analyze the system holistically. The algorithms determine the operating set points and parameters that minimize energy use across the entire plant at all times, and make continuous, automatic adjustments to the system based on the building load and environmental conditions.

The energy improvements from these patented algorithms can be measured in many ways:

- Energy usage savings (kWh/yr)

- Demand savings (kW)

- Non-electrical savings (Therms)

- Cooling tower water usage savings (gal/yr)

- Carbon footprint reduction (lbs/yr)

- PUE Reduction

However you measure it, the results are quantified, predictable, and sustainable for long-term operations, and easily adjusted to accommodate changes in the data center infrastructure.

THE THREE LAWS OF OPTIMIZATION

According to Optimum Energy’s CTO Ben Erpelding, “True HVAC optimization solutions are achieved by implementing the Three Laws of Optimization:”

1. You cannot optimize what you cannot measure. Without an accurate measure of energy use by each piece of equipment in the system, it is impossible to accurately predict the impact of varying conditions on the system.

This requires overall system metering, precise measurement and verification of plant energy savings, detailed real-time performance data, and historical trend analyses to verify plant optimization performance.

2. Optimize systems, not just individual components. If an optimization plan focuses only on installing the most efficient pieces of equipment — without regard to how to maximize performance of the whole system — it will fail to capture the total available system efficiency.

Holistic automatic optimization of HVAC systems typically improves energy efficiency much more than do equipment controls alone.

3. Optimization must be automatic, dynamic, and continuous. For maximum efficiency, optimization should be a real-time dynamic process, not a static process. If a plant’s operational control is not based on real-time inputs, it cannot be fully optimized.

According to Erpelding, Optimum Energy continuously measures and verifies operating conditions and cooling requirements and dynamically adapts system equipment in real time to maintain peak efficiency. “We call this process Real-Time Dynamic Commissioning™, and it is at the core of our success with data center HVAC energy management,” he said.

As discussed above, the Three Laws of Optimization include precise measurements and feedback, a holistic system-wide approach, and a real-time dynamic process. The successful implementation of all of these three laws is a fundamental requirement for an optimized operation.

OPTIMIZING DATA CENTER COOLING SYSTEMS

|

| Figure 1: Value of the automated continuous adaptation and commissioning of equipment. |

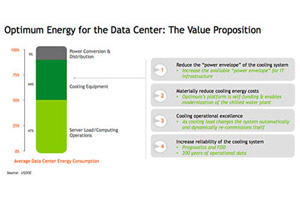

As Figure 1 indicates, the Optimum Energy system focuses on four areas in its approach to optimizing data center cooling systems:

• Reduce the power envelope of the cooling system, and increase the available power envelope for IT infrastructure

• Materially reduce cooling energy costs through a self-funding energy optimization system

• Enhance cooling operational excellence and prevent performance drift with a system that automatically and dynamically recommissions itself

• Increase reliability of the cooling system through fault detection and diagnostics, powered by 200 years of operational data

Optimum Energy implements its solution with a scalable optimization architecture that enables operational design efficiency. On-premise software holistically optimizes the entire cooling system, while connected cloud-based services enable data-driven diagnostics and mission-critical operational support. The result is minimized PUE, reduced energy costs, and a substantial extension of the data center lifespan.

ENSURING OPTIMIZATION SAVINGS FOR THE LONG TERM

Data center energy management systems should include an enterprise-grade platform that provides cloud-based measurement, verification, and management of cooling systems. They should also include continuous commissioning functionality that addresses performance drift through dynamic adaptation of the entire cooling system.

Following the third law of optimization, an effective cooling system optimization solution should act as a continuous feedback loop and provide operators with detailed real-time and historical performance data. Providing actionable insights from this data, it should allow operators, facility managers, and engineers to quickly detect, diagnose, and resolve system faults as they occur (following the first law of optimization).

Ideally, such enterprise-grade platforms should provide three key benefits:

- Facilities operational transparency. Full access to real-time data center operating and performance data, with graphical representations of cooling system operations that can zoom out for a multi-site aggregate view, or zoom in on a specific system for greater detail. Energy managers should be able to customize a broad range of performance reports, and produce dynamic, customizable dashboards, and data visualizations.

- Immediate issue resolution. Real-time alarm notifications should enable operators to immediately identify problems and track them to resolution. Notifications should provide clear information to assist in fast analysis and diagnosis of system faults. This type of continuous, real-time verification reduces performance drift—consequently saving energy and maintenance costs.

- Scalability and security. The platform should be scalable and enable energy managers to institutionalize a repeatable program that effectively contains energy and operational expenses. It should be able to meet the unique needs of operators and energy managers, providing insight into plant operations and efficiency metrics.

THE REAL RESULTS

Optimum Energy shared the results of several case studies to demonstrate how effective their approach really is. Here are a few highlights:

• A data center located in California achieved a 14.3% PUE reduction and a 19.4% improvement in energy efficiency (kW/ton) in one year. As a result, CO2 emissions were reduced by over 1.1 million pounds, and energy costs were reduced by over $130,000.

• A northeast-based data center optimized solution resulted in a one-year energy reduction of over 1.7 million kWh and 17% in energy cost savings. The payback at this data center was 1.9 years, and the IRR was 50%.

They are seeing similar results for customers across North America. Erpelding refers back to the Three Laws of Optimization, “By fulfilling all three laws simultaneously we ensure that our software, services, and process repeatedly deliver effective cooling system optimization for our customers.”

CRITICAL FACILITIES ROUNDTABLE

The Critical Facilities RoundTable (CFRT) celebrates its tenth year of service to the data center community of Northern California this year in 2013. CFRT is a non-profit organization based in Silicon Valley that is dedicated to the discussion and resolution of industry issues regarding mission-critical facilities, their engineering and design, and their maintenance. We provide an open forum for our members and their guests to share information and to learn about new mission-critical technologies, with the intention of helping our members improve in technical expertise and to develop solutions for the challenges of their day-to-day critical facilities operations. Please visit our website at www.cfroundtable.org or contact us at 415-748-0515 for more information.